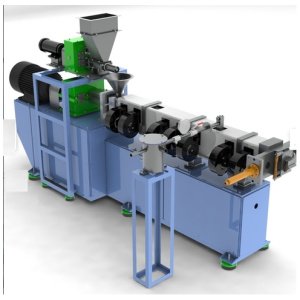

Inline Flat Drip Pipe Extruder Plant offeredfeatures PLC 10.3" touch panel for easy controlling of the operations and providing for maximum line speed of 90 mtrs/min. Further, the high precision servo motor allows optimum control of dripper insertion. Some of the other standard features of these plants include automatic centrifugal screening of dripper before insertion, stainless steel based vacuum tank in 6 meters length, providing for accurate drilling support, servo motor based drive to both the haul-offs, two station coiling in synchronization with the line, automatic coiling machine for changing of coils, providing for high line speed of 120 mts/min and others.

Features:

- Maximum line speed of 90 mtrs/min

- Complete line is controlled by PLC 10.3" touch panel.

- Dripper insertion is controlled by high precision servo motor.

- Dripper is automatically screened centrifugally before insertion

- Vacuum tank is of stainless steel 6 mts long

- Drilling is highly accurate by servo motor and controlled by PLC.

- Drive to both the haul-offs is given through servo motor

- Two station coiling in synchronization with the line.

- The coiling machine is fully automatic and can change the coils

from first coil to the second coil after desired length is complete and cut the pipe

.Hence making the changeover fully automatic.

PRODUCT RANGE :

| Extruder/kw/kg/hr | 75 mm/55kw/150-200 kr/hr |

| Line speed | 30-90 mts/min |

| Cylindrical drippers maximum | 300/min/servo controlled complete line controlled by -10.3" PVC touch panel |

| Transmission speed selection | |

| Emitter spacing | 20cm above set arbitrary (Variable pitch settings) |

| Tractor speed | 10-120m/min |

| Drilling Speed | 250/min |

| Line Length | 38m |

| Line width | 3m |

| Rated Power | 90kw |

| Vacuum Tank | 5 mtrs (Stainless Steel) |

| Water tank | 6*2 mtrs (Stainless Steel) |

| Dripper insertion | Servo controlled |

| Dripper gluing | Servo controlled |

| 1st and 2nd Haul – off | Servo controlled |

| Drilling | Servo controlled |

| Coiler | Automatic coil change |