Circular economy and sustainable production are increasingly becoming the focus of interest in the plastics industry.

Sustainability refers not only to the processing of sustainable, biocompatible materials but to the entire production process. It is important, for example, that a stable injection molding process can be guaranteed even under fluctuating environmental conditions, so that scrap can be kept to a minimum.

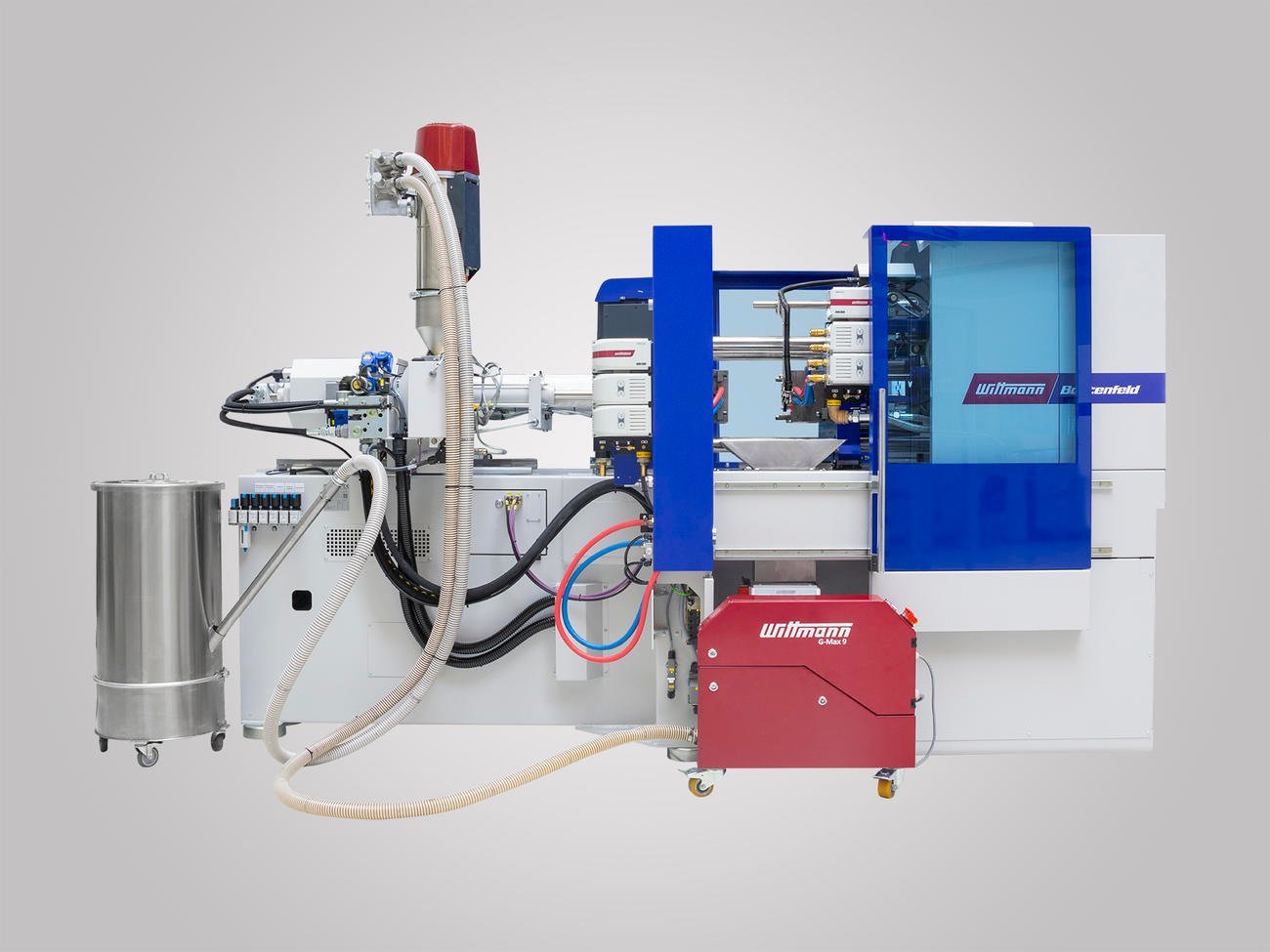

This product is an injection molding system with an integrated sprue picker, granulator, and material loader with a dual proportioning valve. The granulator and the sprue picker can be operated via the machine’s UNILOG B8 control system.

The fully integrated One-Stop-Shop Ingrinder WorkCell includes the following features:

- Injection Molding Machine

- Sprue Picker

- Sprue drop-out chute

- Granulator with low hopper

- Dual proportioning valve for blending virgin plastic material with regrind

- Material loader

- HiQ Flow® – application software for the compensation of viscosity fluctuations

- WITTMANN BATTENFELD's solution for plastic recycling