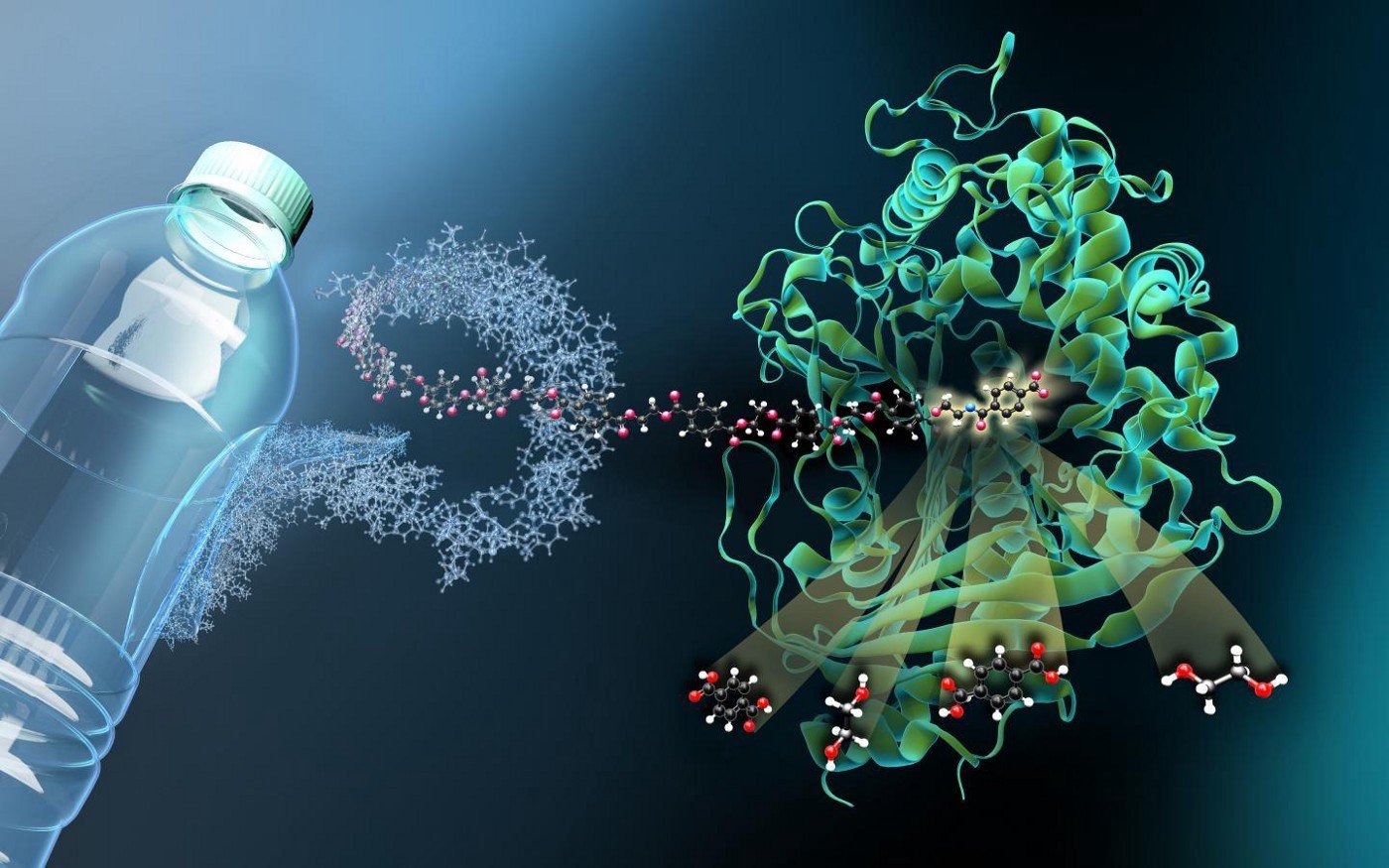

An enzyme variant created by engineers and scientists at The University of Texas at Austin can break down environment-throttling plastics that typically take centuries to degrade in just a matter of hours to days.

This discovery, published today in Nature, could help solve one of the world’s most pressing environmental problems: what to do with the billions of tons of plastic waste piling up in landfills and polluting our natural lands and water. The enzyme has the potential to supercharge recycling on a large scale that would allow major industries to reduce their environmental impact by recovering and reusing plastics at the molecular level.

“The possibilities are endless across industries to leverage this leading-edge recycling process,” said Hal Alper, professor in the McKetta Department of Chemical Engineering at UT Austin. “Beyond the obvious waste management industry, this also provides corporations from every sector the opportunity to take a lead in recycling their products. Through these more sustainable enzyme approaches, we can begin to envision a true circular plastics economy.”

The project focuses on polyethylene terephthalate (PET), a significant polymer found in most consumer packaging, including cookie containers, soda bottles, fruit and salad packaging, and certain fibers and textiles. It makes up 12% of all global waste.

The enzyme was able to complete a “circular process” of breaking down the plastic into smaller parts (depolymerization) and then chemically putting it back together (repolymerization). In some cases, these plastics can be fully broken down to monomers in as little as 24 hours.

Researchers at the Cockrell School of Engineering and College of Natural Sciences used a machine learning model to generate novel mutations to a natural enzyme called PETase that allows bacteria to degrade PET plastics. The model predicts which mutations in these enzymes would accomplish the goal of quickly depolymerizing post-consumer waste plastic at low temperatures.

Through this process, which included studying 51 different post-consumer plastic containers, five different polyester fibers and fabrics and water bottles all made from PET, the researchers proved the effectiveness of the enzyme, which they are calling FAST-PETase (functional, active, stable and tolerant PETase).

“This work really demonstrates the power of bringing together different disciplines, from synthetic biology to chemical engineering to artificial intelligence,” said Andrew Ellington, professor in the Center for Systems and Synthetic Biology whose team led the development of the machine learning model.

Recycling is the most obvious way to cut down on plastic waste. But globally, less than 10% of all plastic has been recycled. The most common method for disposing of plastic, besides throwing it in a landfill, is to burn it, which is costly, energy intensive and spews noxious gas into the air. Other alternative industrial processes include very energy-intensive processes of glycolysis, pyrolysis, and/or methanolysis.

Biological solutions take much less energy. Research on enzymes for plastic recycling has advanced during the past 15 years. However, until now, no one had been able to figure out how to make enzymes that could operate efficiently at low temperatures to make them both portable and affordable at large industrial scale. FAST-PETase can perform the process at less than 50 degrees Celsius.

Up next, the team plans to work on scaling up enzyme production to prepare for industrial and environmental application. The researchers have filed a patent application for the technology and are eying several different uses. Cleaning up landfills and greening high waste-producing industries are the most obvious. But another key potential use is environmental remediation. The team is looking at a number of ways to get the enzymes out into the field to clean up polluted sites.

“When considering environmental cleanup applications, you need an enzyme that can work in the environment at ambient temperature. This requirement is where our tech has a huge advantage in the future,” Alper said.

Alper, Ellington, associate professor of chemical engineering Nathaniel Lynd and Hongyuan Lu, a postdoctoral researcher in Alper’s lab, led the research. Danny Diaz, a member of Ellington’s lab, created the machine learning model. Other team members include from chemical engineering: Natalie Czarnecki, Congzhi Zhu and Wantae Kim; and from molecular biosciences: Daniel Acosta, Brad Alexander, Hannah O. Cole, Yan Jessie Zhang and Raghav Shroff. The work was funded by ExxonMobil’s research and engineering division as part of an ongoing research agreement with UT Austin.

3 comments on “Plastic-Eating Enzyme Could Eliminate Billions Of Tons Of Landfill Waste : University Of Texas At Austin”

eco product

Hi! Do you know if they make any plugins to assist

with SEO? I’m trying to get my website to rank for some targeted

keywords but I’m not seeing very good gains.

If you know of any please share. Kudos! I saw similar art here: Blankets

spiritual healing potion

Self-sufficiency paying your payments is one thing; a do-it-your self angle around the home is somewhat more daunting.

sugar defender official website

sugar defender official website Discovering Sugar Defender has actually been a

game-changer for me, as I’ve always been vigilant about

managing my blood sugar levels. I currently really feel

equipped and confident in my ability to keep healthy

degrees, and my most current medical examination have reflected

this progress. Having a reliable supplement to complement my a huge resource of

convenience, and I’m genuinely glad for the significant distinction Sugar Defender has

actually made in my overall health.